Plymouth

Citybus Long Life Polyurethane Filter Test

Report

Date:

31st May 2005

Conducted

and produced by: Darran Johnson –

Product Director

Scope

To evaluate a Series 5 filter, so as to achieve a service

period of one year for normal service schedules.

Readings were taken every month to ensure that there

were no problems with restriction during the operating

year through summer and winter conditions over the one-year

period.

Examination of the filter was to be carried out when

each reading had been taken and to show and discuss

with the engineering staff, as to how the contaminants

load onto and into the filter, so that the filters would

not be prematurely discarded based on only a visual

inspection.

Test Procedure

Plymouth Citybus chose a suitable vehicle i.e. Dennis

Dart Euro 2, where a Series 5 filter was fitted into

the existing housing. A reading was taken using a digital

manometer and logged, along with vehicle mileage, so

that a chart of restriction over the time period could

be produced. The manometer was attached to the 1/8th

BSP male pipefitting that the canister restriction indicator

would normally be attached to.

Results

The

filter was returned to Series 5 for evaluation.

The

filter was returned to Series 5 for evaluation.

On a quick initial inspection the filter looked dirty,

with approximately 30% of the outer surface of the filter

plated with contaminants. This normally has the effect

of most engineering staff, changing the filter without

looking more closely at the filter structure below the

outer support cage. A reticulated polyurethane media

filter not only relies partly on surface area for filtration

capacity but also the depth of the media to achieve

its long life capabilities.

The two close-up pictures below show the difference

in contaminant loading from a virtually uncontaminated

pore structure to that of a fully loaded contaminated

structure.

It

is worth remembering that the dirt sticks to the strands

of the polyurethane structure and not the particles

blocking the pores of the polyurethane.

|

|

polyurethane

Structure – minimal contaminant |

polyurethane

Structure – maximum contaminant |

The strand thickening by the contaminants can be seen

in both of the close – up pictures and then it

reaches a point where both strands will meet and block

the pore.

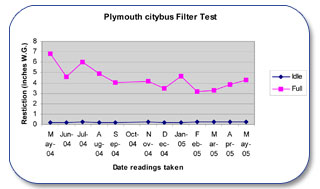

Listed below are the readings that were taken by myself

along with Alan Gavin on my monthly visits to your depot,

noting the mileage of the vehicle for a guideline as

well as time period.

| Vehicle

No.25 |

|

| Date |

Idle |

Full |

Mileage |

Mileage

covered (km) |

| May

12, 2004 |

0.21 |

6.83 |

528387 |

|

| June

16, 2004 |

0.21 |

4.58 |

535720 |

7333 |

| July

27, 2004 |

0.25 |

6.04 |

545545 |

17158 |

| August

25, 2004 |

0.21 |

4.9 |

553429 |

25042 |

| September

28, 2004 |

0.21 |

4.02 |

563162 |

34775 |

| November

8, 2004 |

0.26 |

4.16 |

573039 |

44652 |

| December

6, 2004 |

0.19 |

3.49 |

578473 |

50086 |

| January

12, 2005 |

0.21 |

4.63 |

584902 |

56515 |

| February

14, 2005 |

0.22 |

3.14 |

591177 |

62790 |

| March

17, 2005 |

0.22 |

3.27 |

597849 |

69462 |

| April

20, 2005 |

0.23 |

3.86 |

606411 |

78024 |

| May

19, 2005 |

0.24 |

4.27 |

612129 |

83742 |

Conclusion

A reduction in restriction was noted during the first

9 months of the test followed by an increase, which

would continue through to the end of the full life capacity

of the filter. This is normal due to the fact that as

the dirt loads onto the polyurethane strands, the aerodynamic

effect of the airflow through the filter improves.

There is also a spike in restriction on the January

reading and this was due to it being a very wet day,

which will reduce as the filter dries out.

As the filter media is a composites of plastic, the

filter integrity is unaffected with water being offered

to the filter and no loss of filtration specifications

will be had when the filter dries out. There will be

no premature failures due to Hydrocarbon intake, as

the depth properties of the filter media, have the ability

to absorb these compounds with no increase in restriction.

The

filter has comfortably achieved the “one-year

service life” with a large safety margin for unexpected

high contaminant levels or heavy water ingress from

the environment or bus wash.

I can therefore recommend that changing over to our

“Series 5” range of filters will eliminate

any premature filter failures, while giving a cost reduction

due to the number and frequency of filter changes being

considerably reduced.

Next

>>